MENU

BR | BRL

BR | BRL

-

- Centrífugas de bancada

- Centrífugas de piso

- Centrífugas refrigeradas

- Microcentrífugas

- Centrífugas multiúso

- Centrífugas de alta velocidade

- Ultracentrífugas

- Concentrator

- High-Speed and Ultracentrifugation Consumables

- Diversos

- Tubos

- Placas

- Gerenciamento de dispositivo

- Gerenciamento de amostras e informação

Não foram encontrados resultados

Sugestões de busca

Bioprocess Monitoring and Control

What is bioprocess monitoring and control?

Bioprocess monitoring is the process of continuously measuring key process parameters like pH, temperature, dissolved oxygen, nutrient concentration, and cell status. Bioprocess control is the process of controlling these parameters at a setpoint. Monitoring and controlling critical process parameters is needed to create a culture environment that ensures maximum productivity and product quality.

Read on to learn how to optimize monitoring and control of critical process parameters. If you want to know more about identifying these parameters, learn more about bioprocess development .

Read on to learn how to optimize monitoring and control of critical process parameters. If you want to know more about identifying these parameters, learn more about bioprocess development .

Read more

Read less

How does bioprocess monitoring work?

Bioprocess monitoring is achieved using sensors. They can be placed directly in the culture medium or measure parameters in samples taken from the bioreactor.

Read more

Read less

Which bioprocess parameters are relevant?

There are several key parameters which are typically monitored in a bioprocess, including

Find more detailed information about why and how to monitor and control some of them on our websites on DO control in bioreactors and pH control in bioreactors . See our process analytical technology website for some examples of glucose control in bioreactors.

- Physicochemical parameters, like pH, dissolved oxygen (DO), temperature

- Nutrient concentrations, such as glucose and glutamine

- Byproduct concentrations, such as lactate and ammonia

- Information about the culture, such as biomass, viability, product concentration

- Parameters relevant for conducting the bioprocess, such as liquid level and foam formation

Find more detailed information about why and how to monitor and control some of them on our websites on DO control in bioreactors and pH control in bioreactors . See our process analytical technology website for some examples of glucose control in bioreactors.

Read more

Read less

How are parameters monitored in real-time?

Real-time measurements are conducted in-process, providing continuous monitoring to improve accuracy and efficiency. This can be achieved using either on-line or in-line techniques. For in-line measurements, the sensor is placed directly inside the bioreactor to measure the parameter in situ. With on-line measurements, the sample is usually diverted into a by-pass stream, where automatic measurements are taken by the sensor. Process Analytical Technology (PAT) can be implemented into bioreactor systems to provide in-line or on-line bioprocess monitoring. Despite its benefits, real-time bioprocess monitoring and control has only been optimized for a limited set of parameters, including pH, temperature and DO. This technology is less routine for other parameters including cell density, cell viability and metabolite concentrations.

Read more

Read less

How and why are parameters monitored offline, after taking a sample?

Sometimes, the sensor technology for real-time monitoring is not available or is unsuitable for the bioreactor system in use. In this case, process parameters can be monitored offline. For this, samples can be taken from the bioreactor at regular intervals. This can be done either manually or automatically using an autosampler . The latter can help obtaining strong datasets by facilitating sampling 24/7 in regular, short intervals. Process parameters that are often monitored offline include cell viability, product concentration, and byproduct concentrations. Offline monitoring can still be used for process control. For example, offline nutrient concentration readings can be used to manually calculate and administer the volume of feed required to maintain optimal nutrient levels.

Read more

Read less

Can I monitor my bioprocess remotely?

Yes, this is possible when using appropriate bioprocessing software solutions such as DASware® control and BioNsight® cloud from Eppendorf. In this example, sensor data recorded in the bioprocess control software DASware control can be transferred to our cloud solution BioNsight cloud in real time and accessed from anywhere. This allows remote monitoring of your bioprocess.

Read more

Read less

How does bioprocess control work?

Optimal bioprocess control is achieved using feedback control loops. Here, the sensors within these loops continuously monitor the system’s response, providing automated parameter control without the need for human intervention.

Read more

Read less

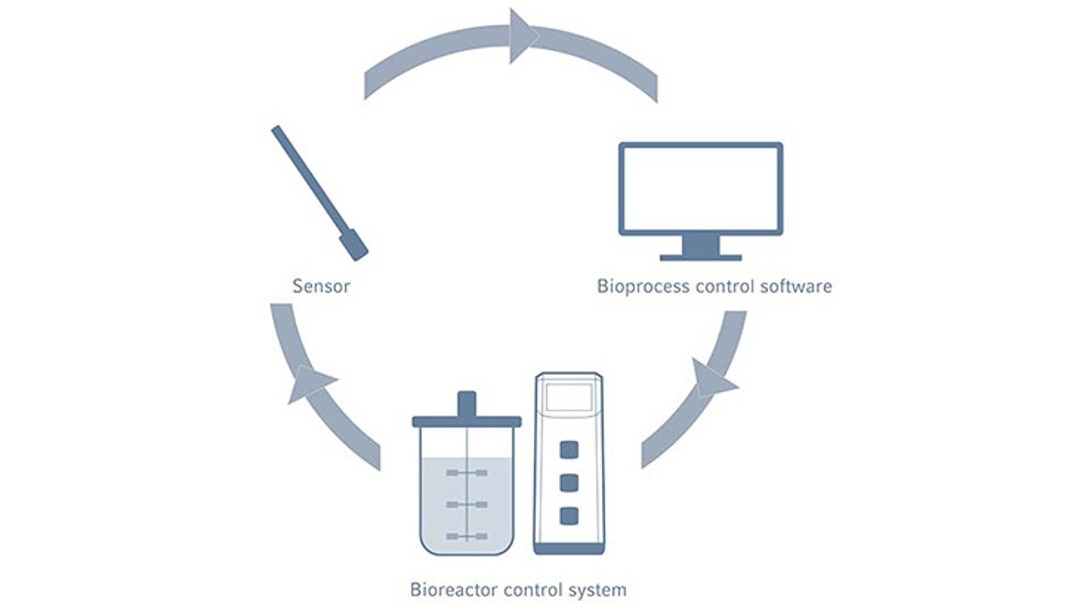

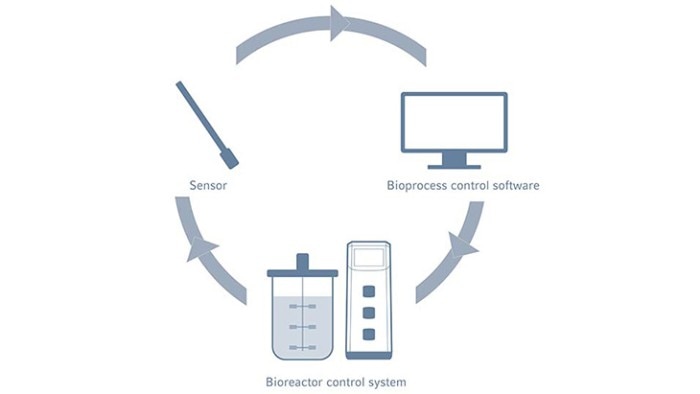

What are feedback control loops? And how can they be used for bioprocess control?

Feedback control loops are used to control process parameters at setpoint. Essentially, these involve the use of sensors that monitor process parameters, transmitting the recorded value to a bioprocess control software integrated into a bioprocess control system. Together, the bioprocess control software and system regulate actuators, which can be for example pumps, valves, or drives, to adjust the parameter back to its optimal level. Feedback control loops are preferred over non-feedback systems, as the sensors within these loops continuously monitor the control system’s response, providing automated parameter control without the need for human intervention.

Read more

Read less

Which process parameters can be controlled with a feedback control loop?

In principle, any! However, a prerequisite of parameter control using feedback loops is the availability of a sensor that monitors the parameter of interest in real-time and is integrated with bioprocess control software. Sensors for temperature, pH, DO, redox, CO2, and level are seamlessly integrated routinely, but other sensors can be integrated as well, including those to control the concentration of nutrients in the culture and those to analyze the exhaust composition.

Read more about feedback control loops for automated culture feeding in our ebook !

Read more about feedback control loops for automated culture feeding in our ebook !

Read more

Read less

How to monitor and control pH and DO?

Find more detailed information about why and how to monitor and control pH and the dissolved oxygen concentration (DO) on our websites on pH control in bioreactors and DO control in bioreactors .

Read more

Read less

Which parameter setpoints should I use for my process?

There is no general answer to this, as the ideal setpoints will depend on the organism or cell type being cultured and your specific application. For more detailed information about cell culture in bioreactors , stem cell bioprocessing , bacterial fermentation , and yeast fermentation , please refer to application examples and expert advice from our customers and our applications team.

Read more

Read less

Eppendorf solutions for streamlined bioprocess monitoring and control

The Eppendorf bioprocess systems help you optimizing your process monitoring and control strategy and be as flexible as possible.

Read more

Read less

Bioprocess systems*

- Take advantage of precise actuators such as pumps, thermal mass flow controllers (TMFCs), and agitation motors to accurately control process parameters.

- Use analog as well as digital Mettler Toledo® ISM® and Hamilton ARC® sensors.

- Use optical as well as electrochemical and polarographic sensors for pH and DO, respectively.

Bioprocess Autosampler

- Benefit from automated sampling and bolus addition 24/7.

- Store your samples tempered for later analysis.

- Profit from broad compatibility with the Eppendorf small and bench-scale bioreactor systems.

DASware® control software

- For comprehensive process monitoring and control.

- Seamlessly integrate various sensor types.

- Develop scripts for tailored process control loops.

BioNsight® cloud

- Monitor your bioprocess remotely.

- Compare to golden batch in real-time.

- Benefit from advanced data analysis.

- Prepare your data for analysis with AI-based tools.